What is Forging Techniuqe

The soft craftsmanship that ith values and the high-quality industrial technology of cutting and forging that Fujimori, a Tokyo-based workshop, is proud of. The forged collection was created by combining the best of both techniques.

The forging technique has been used in Japan since ancient times by sword smiths, and is also applied to the processing of parts for aircraft due to its reliability in strength. In addition to the delicate casting technique that ith has created in the past, wedding and engagement rings with the strength and refinement of the forging technique are now available. Based on the method of your choice, the craftsmen at our workshop will create a special ring with the warmth of ith by adding surface texture and stone setting.

Forging and Cutting Techniques

Forging is the technique of forging metal to increase its strength and put on the finishing touches to jewellery. When the metal is forged by applying pressure with a special roller or hammer, the air and gas contained in the metal are released, and the metal elements become more closely connected to each other, increasing the strength. It is said to be two to four times stronger than ones made with casting technique.

Cutting is the technique of shaving the width and thickness of a ring evenly using a lathe machine for jewellery, and it is not the performance of the machine itself that makes it possible to adjust the shaving in 0.1mm increments, but the skill and sense of the artisan who uses the machine. The cutting method gives the simple form a sharpness that is different from the warm handwork.

The Forged Design of ith

ith, a small atelier started by a female artisan in Kichijoji, Tokyo. We have been creating wedding and engagement rings with a focus on design, using a feminine unique sensibility to create smooth curves, forms that show off the beauty to the finger, and playful textures on the ring's surface.

The forging and cutting techniques are new forms of manufacturing that combine precision machining with the warmth of the craftsmanship. By pursuing not only the design but also the manufacturing technique and quality, we are creating rings that will live with you for your lifetime.

-

![]()

Extend the Metal

The round wire of metal that is the ring's base metal is extended using a tool called a rolling mill. This process is unique to the forging technique.

-

![]()

Brazing

After extended metal wire and it is shaped into a round circle, they are heated to a temperature close to the melting point of it, and the filler metal called "flux" poured into the joint to create strong permanent bonds to close the circle.

-

![]()

Adjusting the Size

The ring, which has been formed into a closed circle by brazing, is hammered to bring it to the final size. Hitting the ring with a hammer pushes out the air and gas inside the metal increasing the strength of the metal.

-

![]()

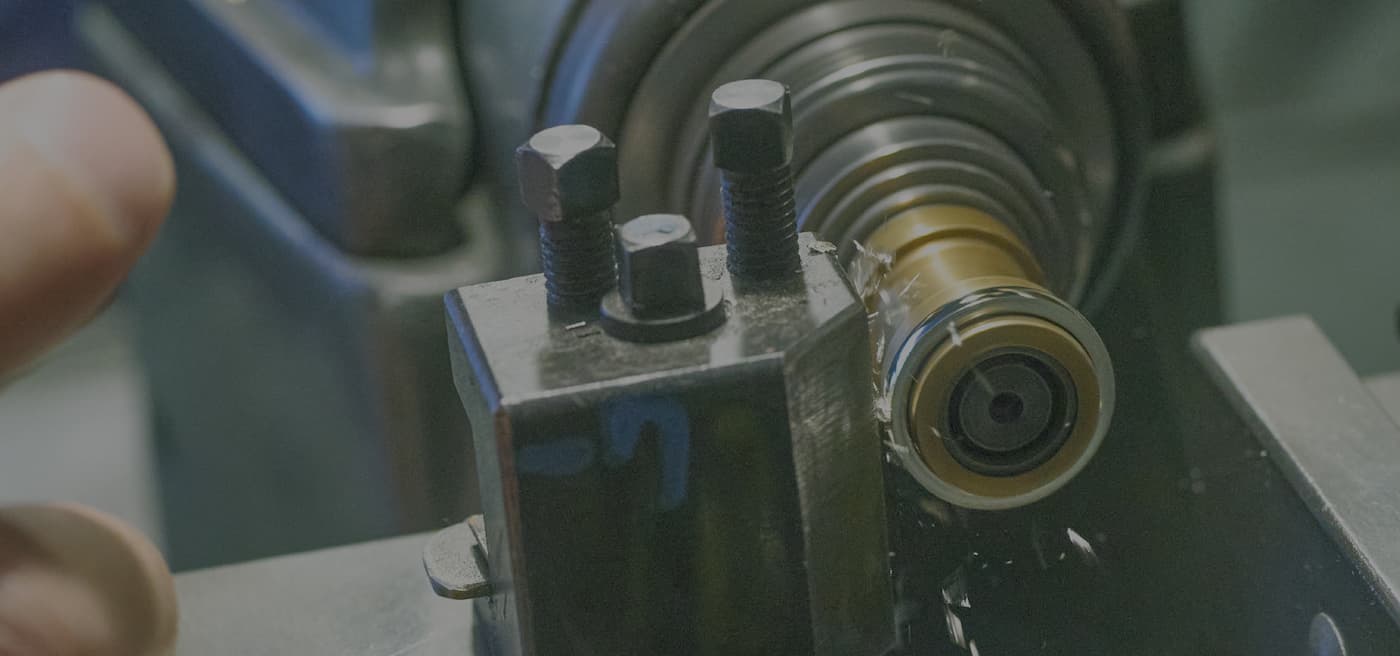

Cutting Technique

This is the process of shaving the width and thickness to the specified dimensions. Using a lathe machine specially designed for jewellery, we cut the sides and then the thickness of the ring in that order.

-

![]()

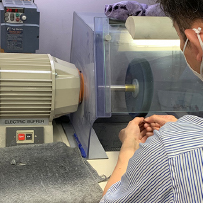

Buffing Process

Once the ring is the specified size, width, and thickness, the final finishing is done. This is the process of polishing the surface of the ring with abrasives to give it a mirror finish.